5 Ways ERPNext Boosts Warehouse Efficiency - Infintrix

Modern warehouse management is no longer just about storage. It's about speed, accuracy, and control. With rising demand and customer expectations, warehous

Modern warehouse management is no longer just about storage. It's about speed, accuracy, and control. With rising demand and customer expectations, warehouse efficiency has become a top priority for logistics-driven businesses. That’s where ERPNext steps in. This powerful platform brings automation, clarity, and real-time control into your warehouse.

In this guide, you’ll discover how ERPNext boosts warehouse efficiency, improves inventory tracking, and helps reduce delays and errors. Whether you run a small storage facility or a large logistics operation, ERPNext can turn your warehouse into a high-performing engine.

Why It Matter

Warehousing today is tough. Orders are piling up, customer expectations are rising, and labor costs are growing fast. Manual systems can’t keep up.

ERPNext warehouse management helps automate routine tasks and centralize data. It gives warehouse teams full control with better speed and accuracy. Let’s look at how it works.

Modern Warehouse Challenges

Many warehouses still rely on spreadsheets or outdated software. This leads to inventory inaccuracy, delayed shipments, and unhappy customers. Mistakes in tracking or picking cost both time and money.

Add in labor shortages, space constraints, and increasing product lines—and things spiral out of control quickly. That’s why businesses are now moving to smart tools like ERPNext for warehouse operations optimization.

Why You Need a Smarter Solution

ERPNext for stock management provides automation, alerts, and data insights. It tracks everything in real time—from items on shelves to shipments in transit. No more guessing where your inventory is.

It also integrates with sales, purchase, and manufacturing modules. That means fewer silos, faster decisions, and real-time inventory visibility across your entire operation.

Why Warehouse Efficiency Matters Today

Inefficient warehouses cost money. According to industry reports, global logistics losses reach over $1.1 trillion every year. That’s a massive hit from errors, delays, and outdated systems.

Here’s how inefficiency hurts your business:

| Problem | Impact |

| Inventory shrinkage | Up to 15% due to theft or manual errors |

| Slow dispatch | Lost sales and customer dissatisfaction |

| Stockouts & overstocking | Revenue loss and high holding costs |

| Poor warehouse productivity | Wasted labor and space |

The Real-World Impact

When customers don’t get their orders on time, they leave. When staff spend hours finding misplaced items, costs go up. With no visibility, your entire supply chain weakens.

ERPNext logistics brings control back. It cuts waste, reduces operational costs, and helps businesses grow fast and smart.

What is ERPNext?

ERPNext is a cloud-based, open-source ERP built to manage every part of your business—especially your warehouse. It combines smart tools for inventory management, shipping, billing, and logistics in one place.

With ERPNext, you get a unified platform for warehouse automation software that grows with your business. It’s perfect for manufacturers, ecommerce companies, distributors, and 3PL logistics providers.

Core Warehouse Features in ERPNext

- Real-time inventory tracking across locations

- Barcode integration in ERP for fast picking and packing

- Multi-warehouse support and bin-level accuracy

- Smart reorder levels and demand forecasting

- Integrated shipping and ERPNext route optimization

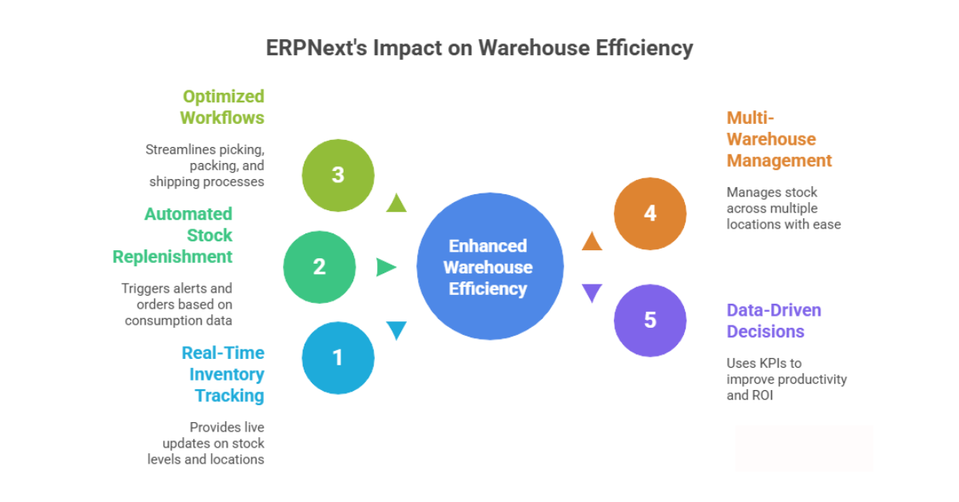

5 Ways ERPNext Supercharges Warehouse Efficiency

1. Real-Time Inventory Tracking and Visibility

ERPNext gives you a live view of your inventory. You can see what’s in stock, where it’s stored, and how fast it’s moving. No more manual counts or outdated reports.

With real-time warehouse tracking in ERPNext, you avoid stockouts and minimize inventory errors. It improves both order speed and accuracy.

2. Automated Stock Replenishment and Reorder Alerts

ERPNext uses your sales and consumption data to set smart reorder points. When inventory drops, it sends alerts or even creates purchase orders automatically.

This helps you optimize inventory control with ERPNext and avoid dead stock. It’s perfect for just-in-time inventory strategies.

3. Optimized Picking, Packing, and Shipping Workflows

Define pick zones, packing rules, and shipping integrations all within ERPNext. Use barcodes to move items faster with fewer errors.

ERPNext connects with major carriers like FedEx and DHL for fast dispatch. It’s a complete system for ERPNext order fulfillment.

4. Multi-Warehouse and Bin Management

With ERPNext warehouse transfer and bin management, you can control stock across multiple locations easily. Each bin can be tracked separately for better accuracy.

Whether you're running two warehouses or twenty, ERPNext provides end-to-end warehouse visibility with smooth internal transfers and stock audits.

5. Data-Driven Decisions with Warehouse KPIs

ERPNext tracks key metrics like lead time, picking accuracy, and stock movement. These numbers appear on your dashboard in real time.

With this data, you can reduce warehouse cycle time, improve staff productivity, and boost ROI. It’s warehouse automation ERPNext style.

Performance Results: What Kind of Boost Can You Expect?

Businesses using ERPNext see big gains. Here’s what the numbers show:

- 6x to 8x improvement in picking and packing speed

- 30% reduction in inventory holding costs

- 80% fewer errors in order fulfillment

- Near 100% accuracy in inventory tracking

Case Study: A Real Example

A mid-sized electronics distributor in Florida switched to ERPNext. Within 3 months:

- Dispatch time dropped by 60%

- Stockouts were eliminated

- Warehouse labor was reduced by 25%

“We finally had visibility into what was happening in real time. ERPNext changed everything,” said their operations lead.

Who Should Use ERPNext for Warehouse Management?

ERPNext works for businesses of all sizes. It’s especially useful for:

- Small and medium manufacturers

- Ecommerce retailers

- Wholesale distributors

- 3PL warehouse providers

Why ERPNext Works for You

- Affordable, even for small teams

- Fully open-source—no license fees

- Scales with your growth

- Easy to customize for specific needs

- Strong ERPNext dashboard for warehouse KPIs

Getting Started: How to Implement ERPNext in Your Warehouse

You don’t need to be a tech expert. Follow this basic ERPNext rollout plan:

- Map your current warehouse process

- Set up inventory, warehouse, and logistics modules

- Import stock data and set bin locations

- Train your team using live dashboards

- Go live and start tracking KPIs from day one

Pro Tip: Work With Experts

You can always work with a certified ERPNext partner to avoid mistakes and save time. Or join the active ERPNext community for guidance.

ERPNext implementation can be completed in just 4–12 weeks, depending on your setup.

Need Help with ERPNext Implementation?

Implementing ERPNext can be seamless with the right partner. Our experienced team offers tailored ERPNext implementation services—from system setup and module configuration to staff training and ongoing support.

Get in touch to streamline your warehouse operations with expert ERPNext support.

Conclusion

Modern warehouses need more than shelves and staff. They need smart systems that scale, track, and automate everything.

ERPNext offers a powerful way to:

- Improve inventory accuracy

- Streamline warehouse workflows

- Cut down on delays and errors

- Enable real-time decision making

- Boost warehouse ROI with ERPNext

Ready to level up? Fast-track your supply chain with ERPNext today.

Frequently Asked Questions (FAQs)

1. Does ERPNext support multi-location warehouses?

Yes. It offers multi-warehouse support with bin-level control and transfer tracking.

2. Is ERPNext good for small warehouse management?

Absolutely. It’s affordable, easy to use, and designed to grow with small businesses.

3. Can ERPNext automate warehouse tasks?

Yes. You can automate stock reordering, picking, packing, and dispatch using workflows.

4. How long does ERPNext implementation take?

Usually between 4 to 12 weeks, based on your business size and process.

5. What’s better—ERPNext or a traditional WMS?

ERPNext is more flexible. It combines WMS functions with sales, purchasing, and finance—all in one platform.

No comments yet. Login to start a new discussion Start a new discussion